GE Healthcare

Home » Case Studies » GE Healthcare

Resources

Need Help?

Call us or Email

+(47) 911 10 600

post@biowater.no

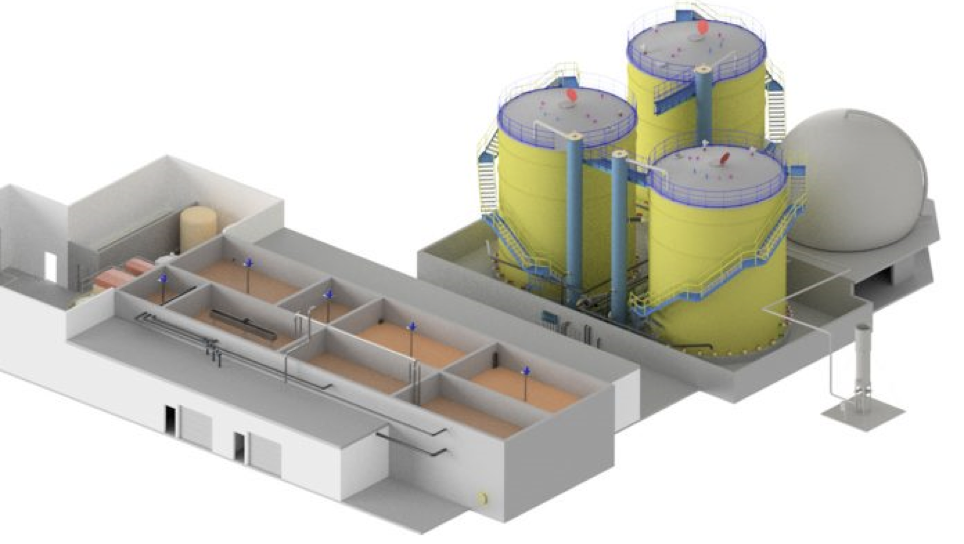

Generating biogas from concentrated wastewater with two-stage biotreatment

The challenge

In 2016, the Zero Emission project was started, which set out to meet the Norwegian environmental authorities’ requirements and look to zero emissions as a long-term ambition. The first step for the facility in Lindesnes has been to develop a solution for reduced emissions of acetate, nutrients and gases, and to look at new solutions for the treatment of wastewater. The goal is to reduce emissions of total COD by at least 95% as well as to achieve low-emission potentials of suspended matter (TSS), nitrogen (TN) and phosphorus (TP).

The design

The process arrangement is based on the HyVAB principal and includes anaerobic expanded granulated sludge reactor (EGSB) for the first step and Biowater’s patented energy-saving aerobic biofilm process (CFIC®) as step two.

Achievements

The during piloting and full scale trial this unique combination of treatment steps was very stable and robust, and exceeded the requirement for a 95% reduction in COD. Under stable effluent conditions, the pilot plant achieved 97 – 98% reduction in COD. A considerable amount of biogas is also produced, which is combusted on site as an energy source.

Highlights

- Project name: Generating biogas from concentrated wastewater with two-stage biotreatment

- Location: GEHCLI - Lindesnes, Norway

- Type of Plant: Biowater HyVAB / CFIC®

- Technology Used: Biowater HyVAB / CFIC®

- Biomedia Used: BWTX

- Operational Since: 2021